Moscow - (Saba):

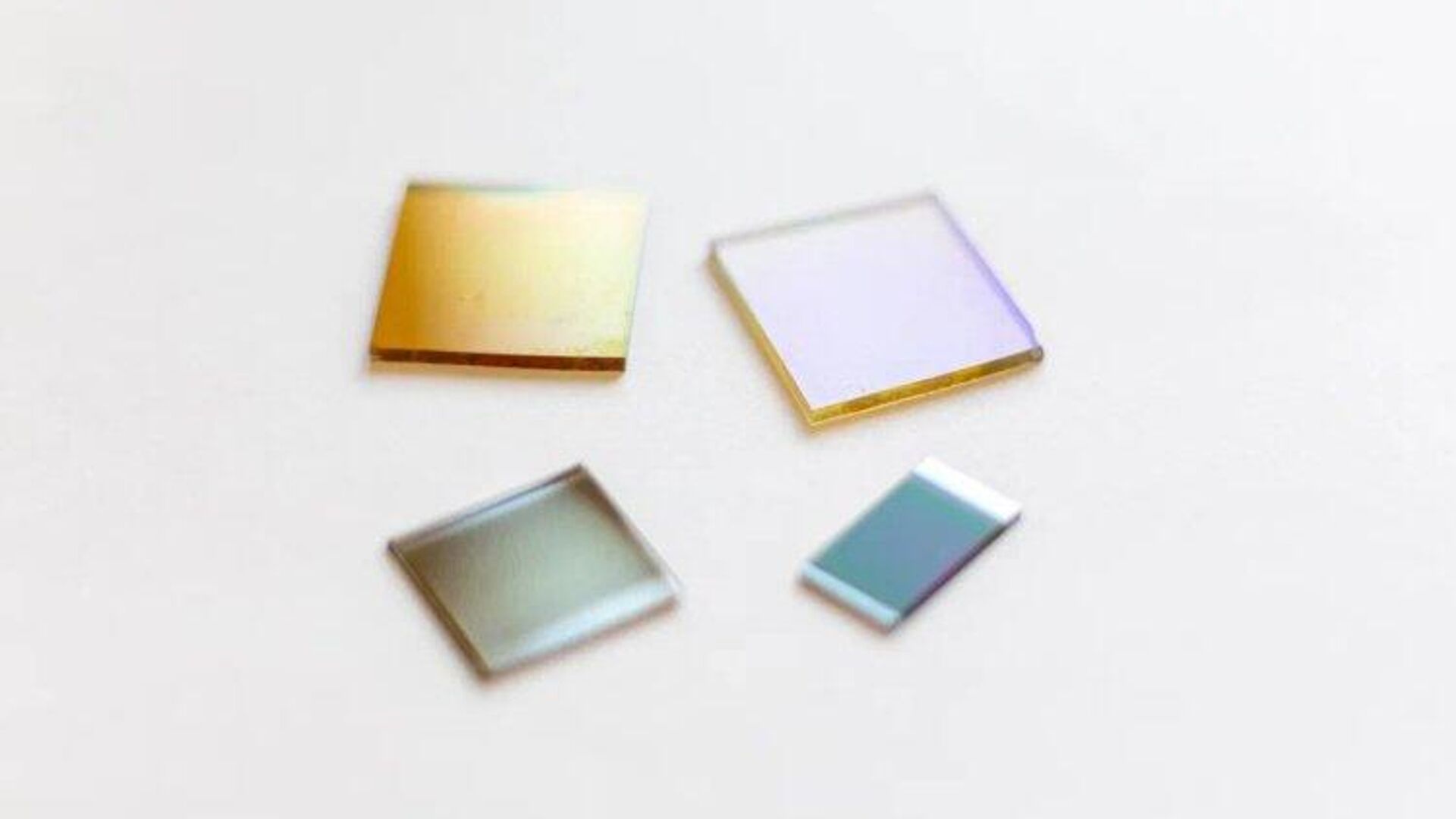

Scientists from the Ural Federal University and the Institute of Electrophysics of the Ural Branch of the Russian Academy of Sciences have developed an innovative coating made of silicon, aluminum, carbon, and nitrogen that can protect aircraft engine components from oxidation at extreme temperatures.

The development combines low synthesis temperatures of up to 400°C, a high deposition rate, and high hardness. All of this will reduce the cost of manufacturing parts and extend the life of civil aircraft and helicopter engines, according to the Scientific Russia portal.

The study, supported by the Russian Science Foundation and published in the journal "Ceramics," features high oxidation resistance at high temperatures.

This means that in an oxygen-containing environment, when heated, a barrier layer is formed due to the aluminum content, preventing oxygen from penetrating deep into the protected material.

The difficulty of obtaining such multicomponent functional coatings is due to the need to create a dense structure with the required chemical elements, according to Andrey Menshakov, a senior researcher at the Laboratory of Photovoltaic Materials at the Ural Federal University and the Institute of Electrophysics of the Ural Branch of the Russian Academy of Sciences.

The coating was obtained using a hybrid technology combining aluminum evaporation and plasma activation of organosilicon.

Experiments have shown that the new material has a hardness of up to 31 gigapascals (comparable to diamond-like coatings) and a dense, defect-free structure.

By comparison, conventional methods for creating such protective films on the surface of turbine elements require temperatures above 1,000 degrees Celsius and often lead to the formation of various defects.

Over two years, the scientists conducted more than ten series of tests, resulting in the creation of several hundred samples.

According to the researchers, choosing the optimal conditions made it possible to achieve the formation of a dense nanostructured coating with the desired chemical composition, ensuring the new composite's high mechanical properties.

Andrey Menshakov added, "We were able to vary the compounding conditions over a wide range, and the process itself is carried out at relatively low temperatures (100, 200, 400 degrees Celsius). This allows the application of protective coatings not only to steel and titanium products, but also to low-melting materials such as polycarbonate."

We also face no obvious restrictions on scaling the facility for industrial production; in this case, everything depends directly on the task at hand.

Plans include testing the coating on real components of gas turbines and jet engines, as well as adapting the technology for other industries.

| more of (International) |